Sanding wood with the belt sander

Description

Nowadays, a large belt sander is often available in workshops for sanding wood surfaces.

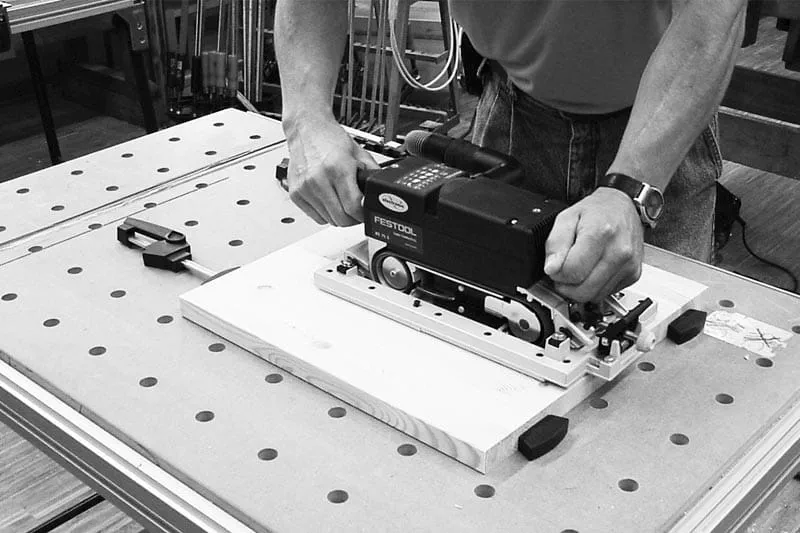

The linear sanding motion, along the grain, results in an excellent sanding result. Alternatively, if a stationary belt sander is not available, for example, there are a variety of hand-guided sanders to choose from. However, when working with an orbital sander or eccentric disc sander, visible rings can form on the surface. This does not occur with mobile belt sanders. Larger surfaces, such as worktops, plates or doors, can also be sanded quickly and safely when these sanders are used in conjunction with a sanding frame. Without the sanding frame, tilting is possible and therefore grooves could be sanded into the surface. This is extremely time consuming to rectify.

Tools/accessories

Preparation/set-up

-

Please make the following preparations for sanding wood surfaces with the tool:

- Insert the belt sander in the sanding frame.

- Turn the front knurled screw to set the cutting depth.

- The material removal capacity can be checked by carrying out a test run.

-

Always use a mobile dust extractor when working, or alternatively, use the long-life filter bag that is included. Both versions protect your health.

Procedure

-

Proceed as follows to sand wood surfaces:

- Place the belt sander on the surface to be sanded.

- Now switch on the belt sander and guide it with S-shaped movements over the workpiece surface. Ensure that you only push the belt sander backwards approx. 2/3 of the belt sander length in each case. This guarantees that transitions between the individual sanding tracks are not visible.

-

- The speed at which the belt sander is moved should be uniform to ensure that material removal is even all over the workpiece.

- Similarly, when processing wood, you should also ensure that the abrasive belt is only moved in the direction of the wood grain. Moving against the grain of the wooden panel can result in sanding marks that are almost impossible to remove.

-

The black handle at the front of the surface sanding frame is used to raise the belt sander off the wood surface as necessary, which permits inspection of the sanded surface even during the work procedure with the tool running.

-

Our illustrated guides and work results are documented working steps that we have performed in practice. They are individual examples and do not guarantee or promise that users will obtain the same results. The results will depend on the user's experience and skill, as well as the material being used. Illustrated guides do not replace any Festool operating manuals and/or safety instructions. Liability for ensuring that the information, instructions and applications are free from content defects and defects of title, in particular with regard to the absence of defects, correctness, freedom from third party intellectual property rights and copyrights, completeness and fitness for purpose, is excluded. Claims for damages made by the user, regardless of their legal basis, are excluded. These liability exclusions are not applicable if the damage was intentional or caused by gross negligence, or in cases of statutory liability.

We cannot accept liability for damage resulting from defects.↑