Profile elements for LED light strips

Professional installation on ceilings and walls

How can extra-long LED light strips be professionally attached? We joined painter Noah Stelzle and his team as they completed a special order, and documented the work steps involved in using the right tool for a creative solution.

The project: A challenging lighting concept

At the headquarters of a German industrial customer, an existing building is being converted into a new customer centre. The focus is on an innovative lighting concept, which infuses the entire room with soft, indirect light through LED light strips set into the walls and ceilings. The most challenging part for the painting company was working on the ceiling, which involved the team having to insert profile elements over a length of up to 13 metres where the stairs are located.

Step by step towards the perfect solution

While the grooving for the profiles on the wall could be made with a router, those in the ceiling area required a circular saw. In order to create a saw guide on the ceiling which was as precise and as long as possible, the Stelzle team connected three guide rails to create a length of 5.70 metres and secured this to the ceiling.

Drawing the marking points on the ceiling

A cross-line laser guarantees a straight cutting line

Attaching the adhesive pads to the extended guide rail

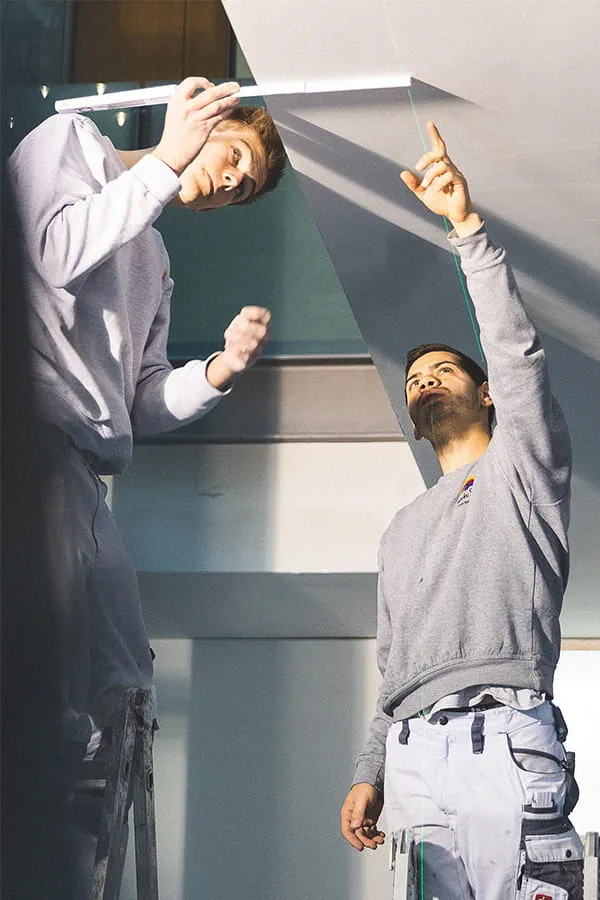

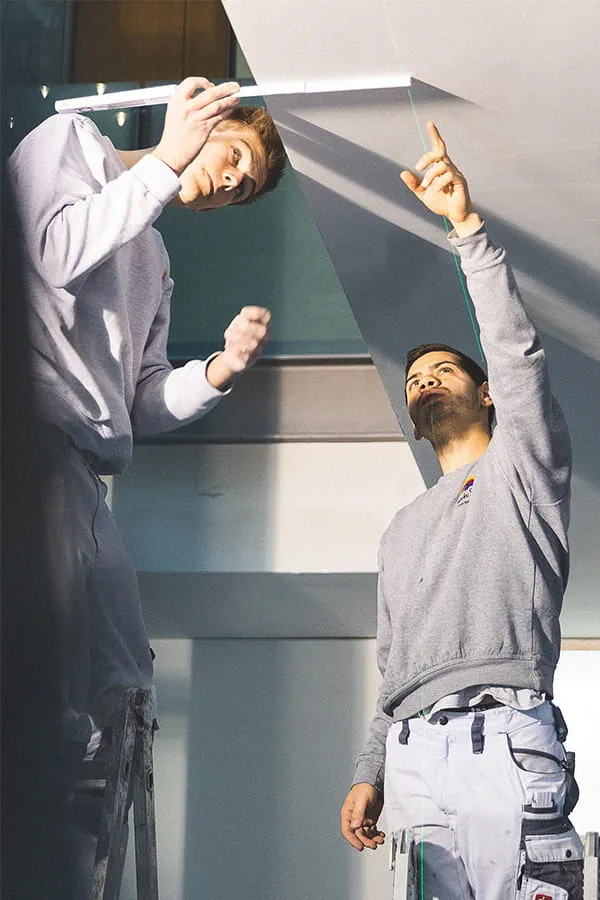

Teamwork and dexterity

Fixing the guide rail with the help of the adhesive pads

Additional fixation by screwing to the ceiling

1 / 1

Accurate upside down too

Using the TSC 55 KEB cordless plunge-cut saw and the Universal Wood saw blade, the first cut is made along the laser line and on the fixed guide rail in a completely straight line. The positioning aid then enables the rail to be moved precisely for the parallel cut according to the profile width.

From the finer work to the end result

With the sawing work completed, Stelzle could remove the material detached between the cuts, and then the team carefully removed the guide rail from the ceiling. The VECTURO OSC 18 cordless oscillator with the USB 50/35/Bi/OSC universal saw blade was used for fine details in the corners. After a final check to ensure an accurate fit, the painters were able to coat the whole ceiling and install the profile strip for the LED light strips bands once it had dried. The result: A modern yet unobtrusive lighting solution, which both the customer and the Stelzle team are absolutely delighted with.

Check: Has the material come loose as planned?

Removing the extended guide rail

Fine work in the corner area with the cordless oscillator

Inserting the profile strip for testing

The result: Modern and unobtrusive lighting

1 / 1

Order successfully completed with innovative solutions: The team is proud of the successful result.

Boss Noah Stelzle, Muharrem Kuyucu, Raphael Berg, Moussa Joulo (left to right)

Boss Noah Stelzle, Muharrem Kuyucu, Raphael Berg, Moussa Joulo (left to right)