Even more robust with DOMINO dowels.

Whether in the workshop, on the construction site or at home: The Festool App is your companion for smart working and perfect results.

Every timber joint has its advantages. The DOMINO Jointing system consisting of a Joining machine and DOMINO dowels combines them all. The unique pendulum routing movement of the DOMINO router cuts precise, torsion-proof slotted holes. The DOMINO dowel combines the stability of mortise and tenon joints with the flexibility of flat dowels. Ideally suited for filigree or solid workpieces indoors and outdoors.

This application example shows how to join construction timbers with the aid of Domino dowels. In the example, the purlins, posts and brace are joined together. These joints serve to secure them in position and aid assembly. To ensure a structurally effective joint, additional appropriate fasteners should be used.

Two round profiles can be joined by a dowel and secured against being twisted using a DOMINO jointer. This illustrated guide explains how to produce custom-fit round profile joints and how to adjust the handrail fence. We recommend making a test cut before beginning work, in order to guarantee good end results for your round profile joints.

This guide gives step by step instructions for creating mitre joints quickly and efficiently. This is performed using the joining machine in conjunction with loose tenons – the oval DOMINO.

Wooden panel joints like those for cupboard or shelving units can be created optimally using the DOMINO joining machines. The following example shows how to create a wooden unit with the joining machine.

We visit Wolters B.V., about one and a half hours east of Amsterdam, a large painting enterprise with more than 100 employees. At its headquarters in Deventer, projects throughout the entire country are prepared and coordinated. Extensive painting work is carried out in the large plant hall and the modern spray booth. But mainly the Wolters teams have to be ready at any time and have everything they need for their work, no matter where they are.

Hafven in Hanover is a fertile breeding ground for creative makers and all those aspiring to be just that. The co-working and makerspace recently celebrated its first birthday – with a table football set. Self-built, of course.

For years, Michael Möllmann had been dreaming of a rocking chair like the one owned by US President John F. Kennedy. Together with joiner Karsten Schillings, this dream became a reality. The professional and the layman worked together as a team to complete the project.

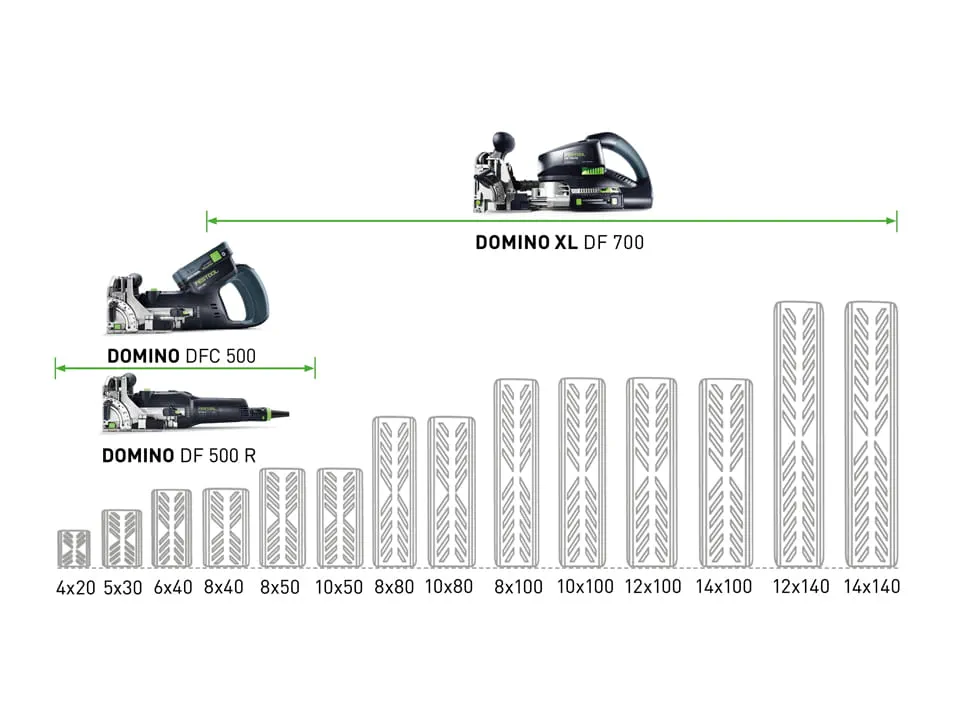

From theory to practice: Clarissa Kellermann is completing a practical semester at Karsten Schillings' joinery workshop. Over the course of this semester, they produced the Tria Omada furniture series. The Festool Domino DF 500 and 700 joining machines proved to be the ideal companion for this project.