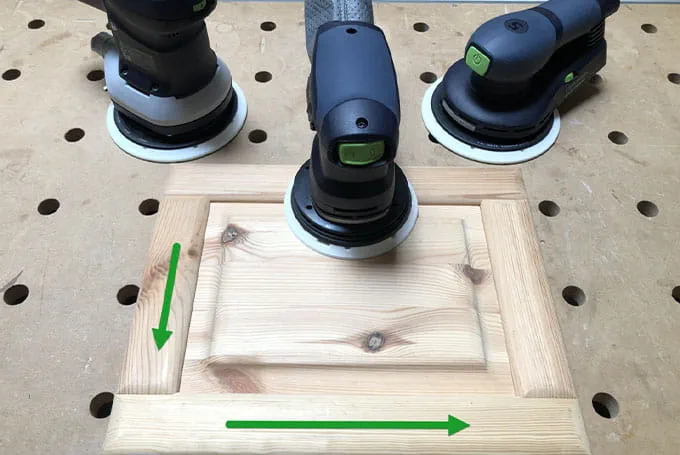

Sanding perpendicular joints

Description

Tools/accessories

Alternative tools

Preparation/set-up

-

The eccentric disc sanders differ in features such as their sanding stroke, the diameter of their sanding pads and their weight. This must be considered if you need to do overhead work, for example. In such cases, the lighter ETS 125 or ETS EC is ideal.

-

If you need to remove large amounts of material, you can sand first with the ROTEX RO 150 geared eccentric sander in coarse sanding mode and then finish with fine sanding in eccentric mode.

-

Dust extraction must be used when sanding.

The ETS 150 and ETS 125 have in-built dust extraction and are supplied together with a filter cartridge. These models can be used outside the workshop when you do not have a dust extractor with you.

All Festool eccentric sanders can be connected to a Festool mobile dust extractor. Using the "plug it" suction hose is especially practical here. If you are sanding painted surfaces, the anti-static model should be used. (Standard feature with Festool)

Procedure

-

Select an abrasive from the Festool accessory range with the right grit for the particular surface quality of the wood. Festool offers the right abrasives for different materials (wood, paint, metal, etc.). For wood, use Rubin 2; for layers of paint over wood, use Granat

• For preliminary sanding of untreated surfaces, use Rubin 2 P 120 abrasives.

• Always guide the tool so that the sanding pad is parallel (horizontal) to the workpiece surface.

• Move the sander evenly over the workpiece.

• Do not spend too long in one place. Remember: The sander removes wood. This can cause dents in the surface.

-

When sanding veneered surfaces, there is risk of "sanding through" the veneer – especially at the edges of the board

To prevent this, use the green thumbwheel to reduce the motor speed, which reduces the rate of material removal.

-

To sand between paint coats, use Brilliant 2 P 220 or P 240 abrasives. Also be sure to follow the recommendations of the paint manufacturer.

-

Note when attaching abrasives to the sanding pad: The holes in the abrasive disc must line up with the holes in the sanding pad. Optimum dust extraction is only possible with the abrasives in this position.

-

Our illustrated guides and work results are documented working steps that we have performed in practice. They are individual examples and do not guarantee or promise that users will obtain the same results. The results will depend on the user's experience and skill, as well as the material being used. Illustrated guides do not replace any Festool operating manuals and/or safety instructions. Liability for ensuring that the information, instructions and applications are free from content defects and defects of title, in particular with regard to the absence of defects, correctness, freedom from third party intellectual property rights and copyrights, completeness and fitness for purpose, is excluded. Claims for damages made by the user, regardless of their legal basis, are excluded. These liability exclusions are not applicable if the damage was intentional or caused by gross negligence, or in cases of statutory liability.

We cannot accept liability for damage resulting from defects.↑