July is the hottest month of the year in eastern Finland. But while much of Europe is sweating under the heat, temperatures in this part of the world hardly climb above 20 degrees on average. It is here, or to be more precise in the city of Joensuu, that Martti Matilaisen's tiling company is located. He therefore knows only too well why his compatriots sometimes want to feel snug and cosy and enjoy a steamy sauna or swimming pool to relax.

However, it is not a cosy environment when Matilaisen and his team start working as the old tiles need to come out and new ones put in, which produces debris and stirs up dust. Moreover, since small repairs are often a precursor to more major work, sometimes the tilers need to pull out the pool's plug straight away so that they can really set to work.

Hot baths tiled by cool operators

A team of tilers for unusual challenges

In Finland, there's nothing better than spending time relaxing in a sauna. People not only enjoy the steam baths but also the very cold indoor swimming pools. Martti Matilaisen and his tiling company, Mestarilaatoitus, specialise in such pools. His company tiles and maintains entire swimming pools and is renowned for its work across the whole of Finland. An important ingredient behind his and his team's success are the tools, considerable expertise and the even greater experience offered by Festool.

Where power meets sensitivity

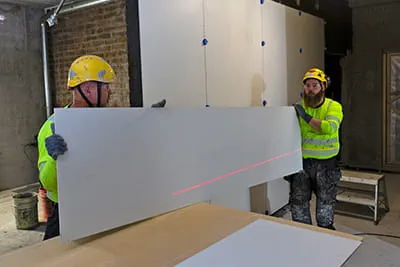

However, one of Mestarilaatoitus' most recent projects was slightly unusual. A newly built swimming pool in Espoo, a city close to Helsinki, needed to be fully fitted – meaning that the team of strongly-built tradespeople faced a considerable amount of work. "The shower facilities at the indoor pool were designed with very large tiles. Some of them measured between one metre and 2.7 metres in size," Martti Matilaisen explains. This demanded a lot even from professionals like him and his team. It took at least two workers to install each tile, gently placing each tile while also looking for any buckling caused by their considerable size.

It was therefore vital that the tradespeople were extremely cautious. They used a great deal of sensitivity to pay attention to the tiles' seals, epoxide compounds and any breaks in the floor. Traditional methods were only useful to a limited extent, with Matilaisen stating that "the job required specialised knowledge."

While that project is now finished, the designing process took a great deal of time and began a year ago. The part which was time-consuming was allowing the preparatory work to dry. "We often needed to take long breaks", says Matilaisen, explaining that they used this time to work on other projects.

While that project is now finished, the designing process took a great deal of time and began a year ago. The part which was time-consuming was allowing the preparatory work to dry. "We often needed to take long breaks", says Matilaisen, explaining that they used this time to work on other projects.

Durable tiles, regular maintenance

Laying tiles for swimming pools is always a challenge. This is because the tiles are very hard and the surface may be glazed or unglazed. What's more, all of the tiles used for swimming pools absorb less than 0.5% water – which is very little. In addition, their roughness grades determine their slip-resistance. For example, in wash rooms, the tiles also need to be easy to wash and clean because a mixture of water and soap residue collects on them and remains adhered.

If they are laid correctly and are of suitable quality, tiles can last for a very long time. For instance, it is not uncommon for pool tiles to remain in use for 30 years. "We even renovated one pool with tiles that were 40 years old," notes Matilaisen, before continuing that their service life may also vary depending on the degree of use. If they are subjected to heavy use, tiles may only have a service life of ten years.

If they are laid correctly and are of suitable quality, tiles can last for a very long time. For instance, it is not uncommon for pool tiles to remain in use for 30 years. "We even renovated one pool with tiles that were 40 years old," notes Matilaisen, before continuing that their service life may also vary depending on the degree of use. If they are subjected to heavy use, tiles may only have a service life of ten years.

Generally speaking, swimming pools are serviced once a year, particularly during their closing hours in the summer. For Martti Matilaisen and his team, this means that they need to work full speed ahead. For one job at an indoor pool in eastern Finland, they needed to open huge tile joins to replace broken elements. However, this also required great care in order to avoid breaking any of the neighbouring tiles.

Maximum flexibility thanks to the mobile socket

"For projects involving repair work, we often don't have any power and need to lay a lot of extension cables," Matilaisen explains. In such cases, Mestarilaatoitus makes use of the Festool SYS-PowerStation. "It has proven very effective for our work," Matilaisen continues. This power source means that it is no longer necessary to lay guide extensions from dry rooms to the place of use. What's more, the tool, extractor and SYS-PowerStation form a single unit and the power supplied by the mobile socket is sufficient for the entire working day. But if it looks like you might run out of power, simply recharge the SYS-PowerStation during your lunch break. "An excellent investment!"

Festool plays a key role within this Finnish tiling company. "We certainly have a lot of Festool tools, from woodworking machines to various cordless drills, dust extractors, KAPEX cutting saws, bench saws with accessories and a wide range of sanders," Matilaisen states. He believes that Festool tools are a critical factor in producing high-quality work. Moreover, Matilaisen is also impressed by the tools' load capacity and durability.

Festool plays a key role within this Finnish tiling company. "We certainly have a lot of Festool tools, from woodworking machines to various cordless drills, dust extractors, KAPEX cutting saws, bench saws with accessories and a wide range of sanders," Matilaisen states. He believes that Festool tools are a critical factor in producing high-quality work. Moreover, Matilaisen is also impressed by the tools' load capacity and durability.

But that's not all, Matilaisen also uses the Festool MX stirrer for filling material and fastening mortar, as well as the Festool STL SYSLITE and DUO SYSLITE working lights – the latter of which enables users to create the right lighting for working with millimetre precision and without distortion. Other very important pieces of equipment are the Festool TG 130 surface-restoration grinder and the MFT tables, "which always provide excellent platforms when we're cutting tiles," Matilaisen notes. In addition to the SYS-PowerStation, Mestarilaatoitus also uses Festool cordless tools. "They allow us to be mobile and are comfortable and easy to use – all without a cable getting in the way," Matilaisen adds.

Empty swimming pools and delicate tiles

With such equipment, Mestarilaatoitus is prepared for every job and swimming pool – even if the work is sometimes completed within a day or they need to work nights. Needless to say, sometimes entire pools need to be emptied in order to carry out repair work. "But emptying pools is very expensive," says Matilaisen, adding that basins can only be empty for a maximum of four weeks. "After that, cracks start to form because the tiles behave like wood."

There are therefore separate rules for emptying a basin. For instance, it must not be emptied too quickly. For a large swimming pool, only a maximum of 60 centimetres of the water level can be removed per day, and this prevents the tiles from breaking. In addition, the water must be at room temperature when the pool is being filled. If the water is cold, the structures will expand significantly, potentially causing the tiles to break and become detached. Depending on the pool's depth, the filling or emptying process may take up to four days.

There are therefore separate rules for emptying a basin. For instance, it must not be emptied too quickly. For a large swimming pool, only a maximum of 60 centimetres of the water level can be removed per day, and this prevents the tiles from breaking. In addition, the water must be at room temperature when the pool is being filled. If the water is cold, the structures will expand significantly, potentially causing the tiles to break and become detached. Depending on the pool's depth, the filling or emptying process may take up to four days.

Scuba-diving tilers

If individual tiles at a swimming pool are broken, it is often useful for tradespeople to dive into the water to perform the work. "Our workers sometimes have to put on a snorkel to repair the damage," Matilaisen notes, before explaining that this is mostly a remedial measure and such areas will require major work sooner or later. But, for today, Mestarilaatoitus' workers have reached the end of a hard day's work.

Editor's note: This article was produced in full by our locally-based colleagues from Festool Finland – no air miles, with their corresponding CO2 emissions, were incurred.