Living more fairly – building more sustainably

Three students in Vienna are developing a modular concept for construction and living for the residential constructions of the future. The construction materials are sustainable and the idea seems intelligent – but can the concept really be put into practice? We've asked the three creators.

Nikolas Kichler (NK): Architecture graduate from the Vienna University of Technology (TU Wien)

Mikka Fürst (MF): Architecture graduate from TU Wien, course for sustainable construction at TU Wien and TU Graz

Paul Adrian Schulz (PAS): Architecture graduate from the Academy of Fine Arts in Vienna

How did the idea of the vivihouse come about?

What's behind the name "vivihouse" and what is special about this modular construction design?

What are the challenges of building modular houses with over more than one storey?

Paul Adrian Schulz: We see the biggest challenge in logistics, assembly and environmental compliance with fire safety and soundproofing regulations, as well as airtightness and impermeability to driving rain. Another, more general challenge is finding suitable and affordable land.

Who monitors the quality of individual modules and the structural analysis?

NK: The project was conceived such that the outer walls and ceiling elements can be easily assembled. Our workshops are always attended by experts. Since the building is based on prefabrication methods, the elements can easily be checked and removed by maintenance groups. The joints relevant for the structure, as well as the struts, reinforcements, utilities management and the assembly process of the entire building were exclusively carried out by qualified professionals in the case of this prototype.

Which Festool tools are particularly popular with the users?

What is your vision of urban living in the future?

What role does sustainability play?

Can modern architecture be combined with sustainability?

What role will the environment and sustainability play in the construction industry in the future?

Which materials are mainly used?

Who are your customers?

NK: People with an environmental conscience and an interest in participation and design.

Do you have technical training?

NK: No, not per se. However, all three of us have worked as assistants on construction sites – primarily in construction using straw bales.

How much room for creativity is there in the concept of the modular construction kit?

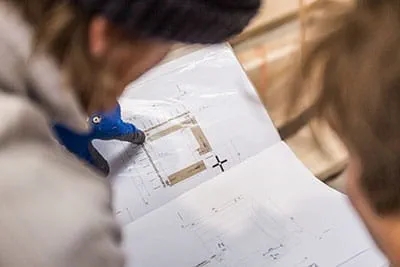

Are there assembly instructions or how can it be envisaged?

How difficult is it to construct a module like that? Can a layperson do it without professional help?

NK: Our workshops always begin with tool and safety training. The next steps are then demonstrated using our assembly instructions. Our workshops are always run with professional help. People who are interested can join in with construction, or simply watch it being built or help in a different way. There is usually enough to do. Our first prototype was primarily built by architecture students. Almost 20% of the contributors were external people who were interested, including experienced tradespeople.

Can the "experience of living" in a vivihouse be compared to a conventional house? Including in terms of energy efficiency?

How much does it costs to build a single module and how is the entire construction financed?

What are the future plans for vivihouse?